Our story

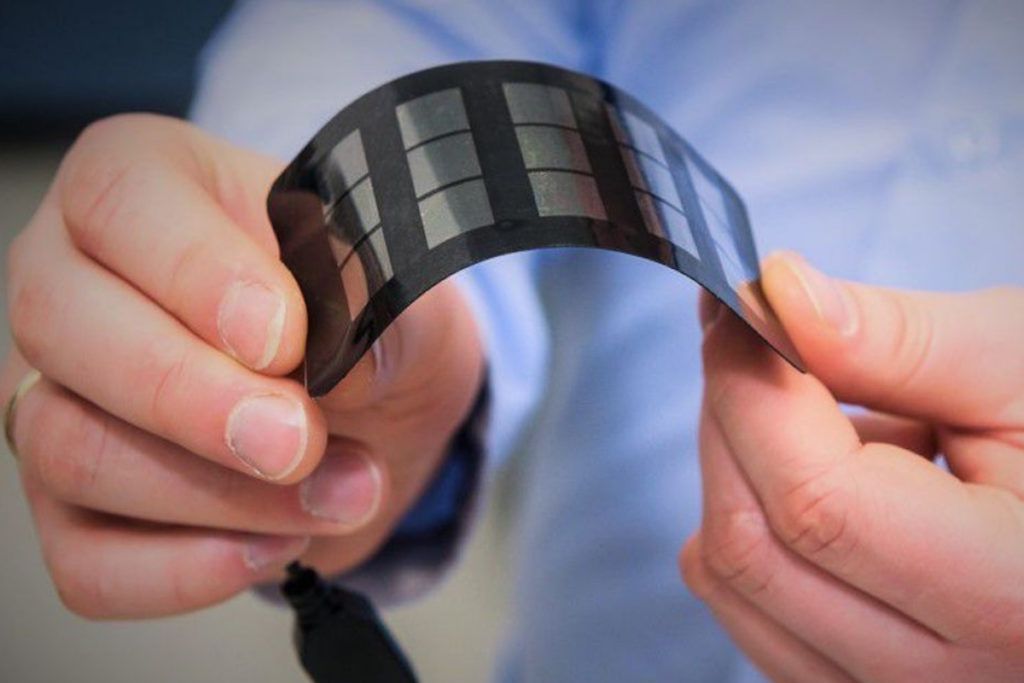

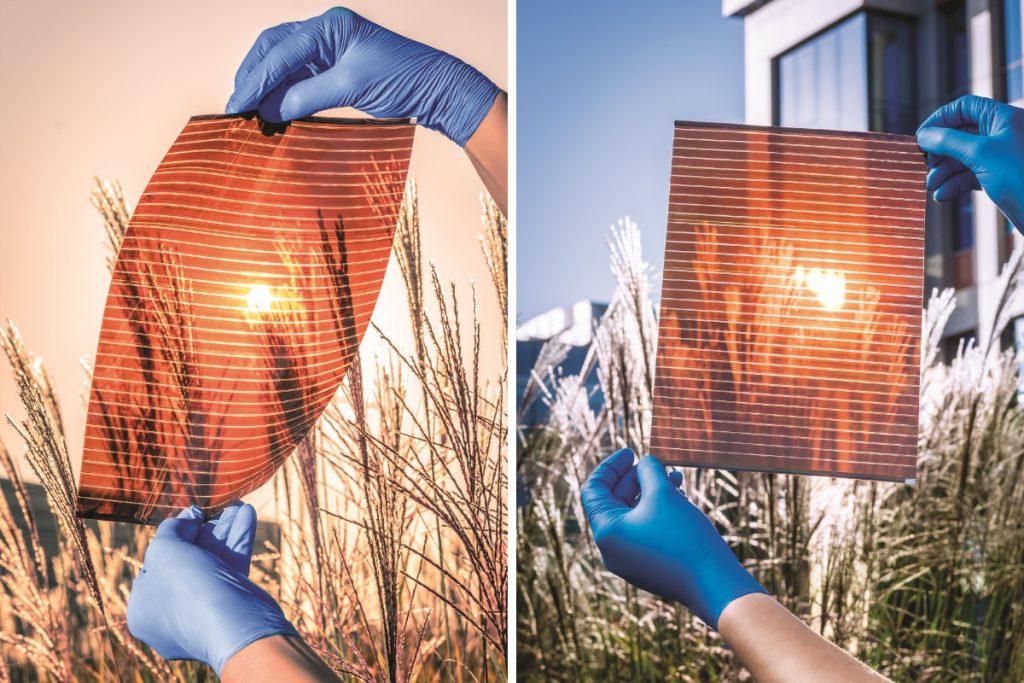

Saule Technologies develops inkjet-printed, ultra-thin, and flexible solar cells based on perovskites.

2013

As a PhD student at the University of Valencia, Olga Malinkiewicz invents a revolutionary method to produce solar cells by coating perovskites on flexible foils. This achievement earns her multiple awards and garners international media attention.

2014

Realizing that her breakthrough has the potential to impact the world on a massive scale, Olga teams up with Piotr Krych and Artur Kupczunas, and Saule Technologies is created.

2015

While Saule Technologies makes active progress in its laboratories, the company receives an investment from well-known Japanese entrepreneur and investor – Mr. Hideo Sawada – represented by Huis Ten Bosch Co. Ltd.

2016

Saule Technologies continues to discover new opportunities through new challenges. The team introduces the first real-life application of perovskite solar cells – a mobile phone charger that operates under artificial light.

2017

As Saule Technologies partners with major players like Ergis and Skanska, our first flexible, A4-sized perovskite solar module on an ultrathin plastic foil is inkjet-printed. The module is demonstrated by charging electronic devices at the IDTechEx Show! in the US.

2018

Another significant milestone is achieved when the Saule Team creates a semi-transparent, A4-sized perovskite module. And our products are tested internationally in Poland (Skanska’s Spark office building in Warsaw) and Japan (Henn na Hotel in Nagasaki).

2019

The first product for the electromobility market is introduced – the Solar Carport. While the dedicated research in our laboratory brings promising results, Saule Technologies starts building the first production line.

2020

After site-acceptance tests and technology transfer, the production line will allow supplying first perovskite-powered products in the IoT and BIPV market. In September, the company received a 10 million euros investment from a Polish silicon PV provider – Columbus Energy.

2021

2021 is a breakthrough year for Saule Technologies, as we are launching the production line. We regularly announce new licensing opportunities for products with perovskite PV integration. In Q1 this year, we signed the first licenses with industry leaders to sell and distribute our solutions.

2022

2022 was a year of continuous work on technology development and looking for new ways of business development. We’ve entered the market of IoT, proposing to our business partners our Perovskite Electronic Shelf Labels.

2023

Saule Technologies became a member of Platform-ZERO – a new project co-funded by the European Commission that aims to reach zero defect manufacturing and substantially reduce production costs for industry in the photovoltaic sector.

Our goal

We want to make solar power accessible to everyone.

Looking For More?

Find answers to the most Frequently Asked Questions.

Check the current Job Openings.

Find news and PR materials on our Press page.

Learn about our Products.

Get in touch with us through the Contact page.

Read our Corporate Information page for organizational info.